Computational Fluid Dynamics (CFD) uses data structures to solve fluid flow problems, such as velocity, density, and chemical compositions.

This technology is used in areas like cavitation prevention, aerospace engineering, HVAC engineering, electronics manufacturing, and way more. You can also hire CFD consulting assistance online.

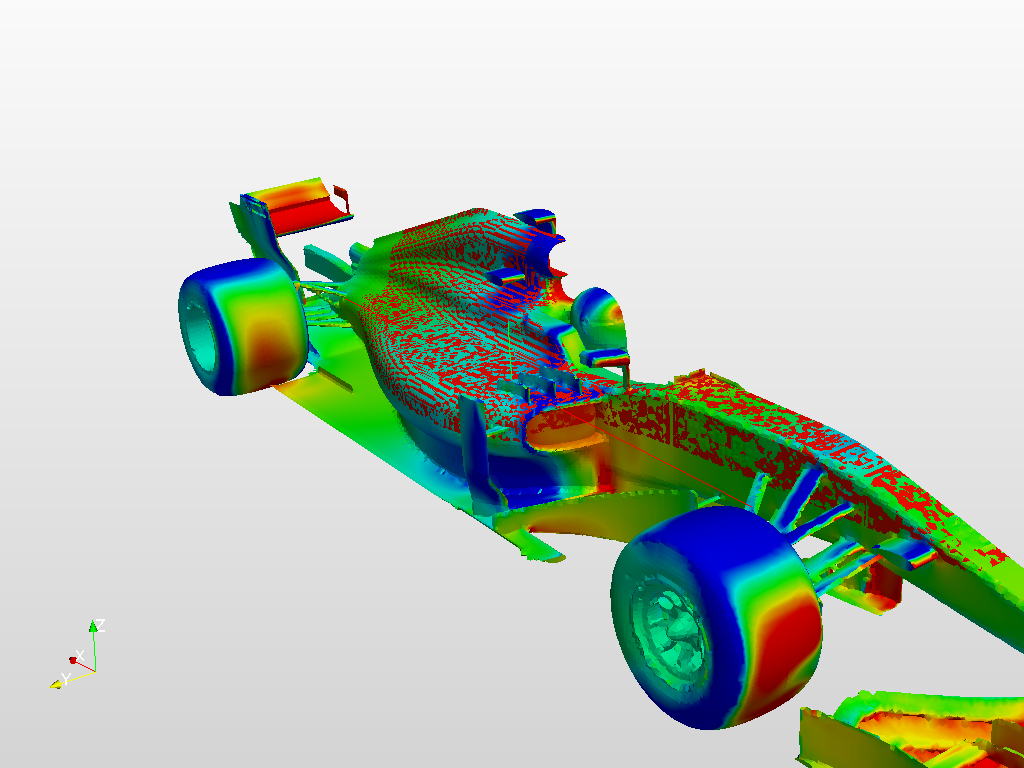

Image Source: Google

Below are a few lists of the most common CFD simulation applications in use today:

1. CFD Simulation for Preventing Cavitation

Cavitation is the formation of vapor bubbles within a liquid and occurs when an object (such as a propeller) moves through the liquid. Cavitation can cause damage to propellers, nozzles, turbines, spillways, and valves.

Cavitation simulation through CFD, however, can help engineers set tiny thresholds that would be difficult to measure in the physical world. They can measure at a very granular level to compare alternative products and designs to improve the flexibility, durability, and safety of their projects.

2. Simulating Rotating Machinery using CFD

Rotating machinery such as compressors, steam pumps, gas turbines, and turbo-expanders have one thing in common: the cyclic load acting on the structure.

Labyrinth seals are used in various rotating types of machinery to reduce leakage flow. The gas passing through the seals often creates a driving force that leads to unstable rotor vibration.

Once again, rather than investing in constant prototyping and physical stress testing, CFD simulation can be used to test a variety of design variables to find the most ideal construction of rotating machinery.